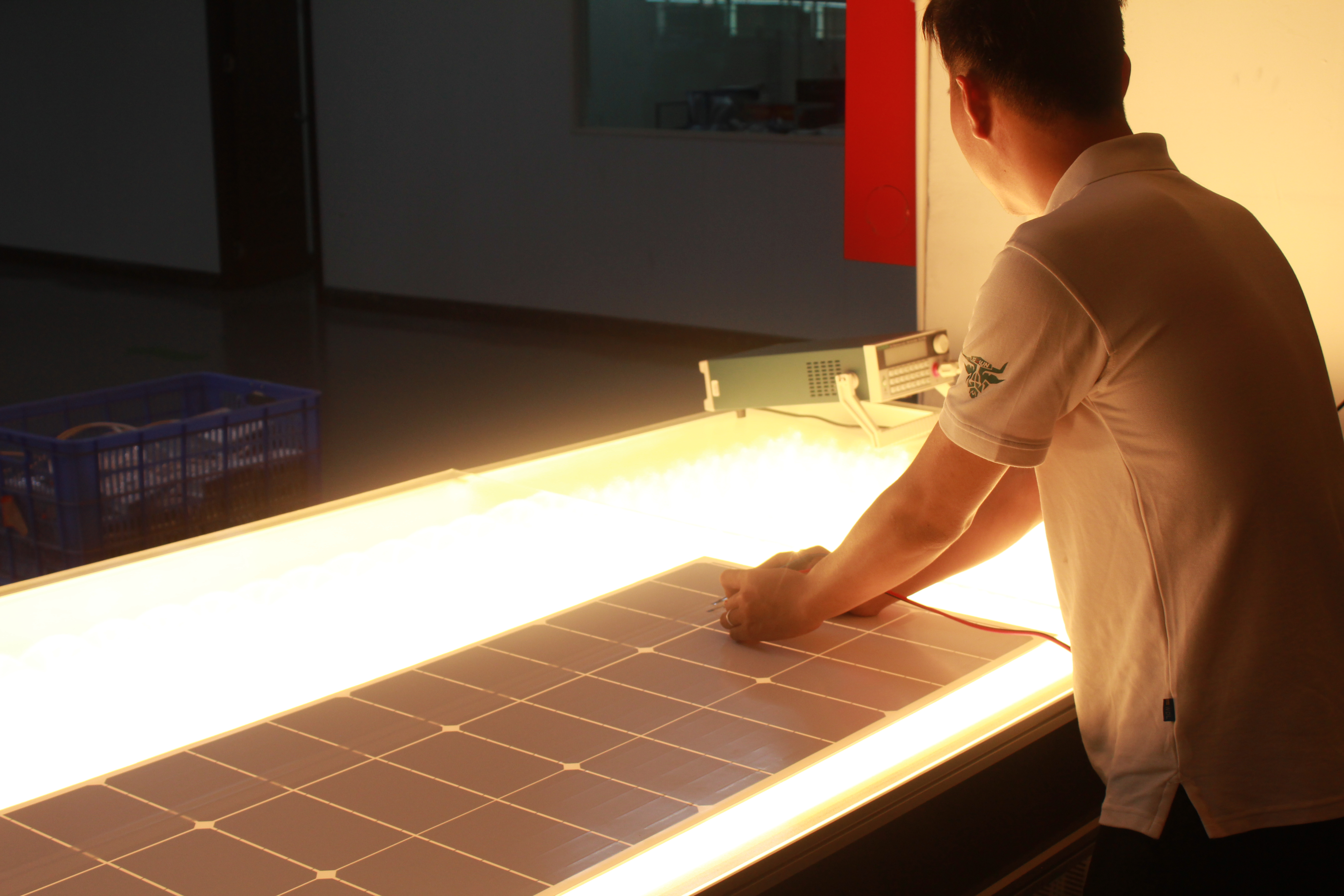

Professional Laboratory

What Does a Solar Panel Test Bench Do?

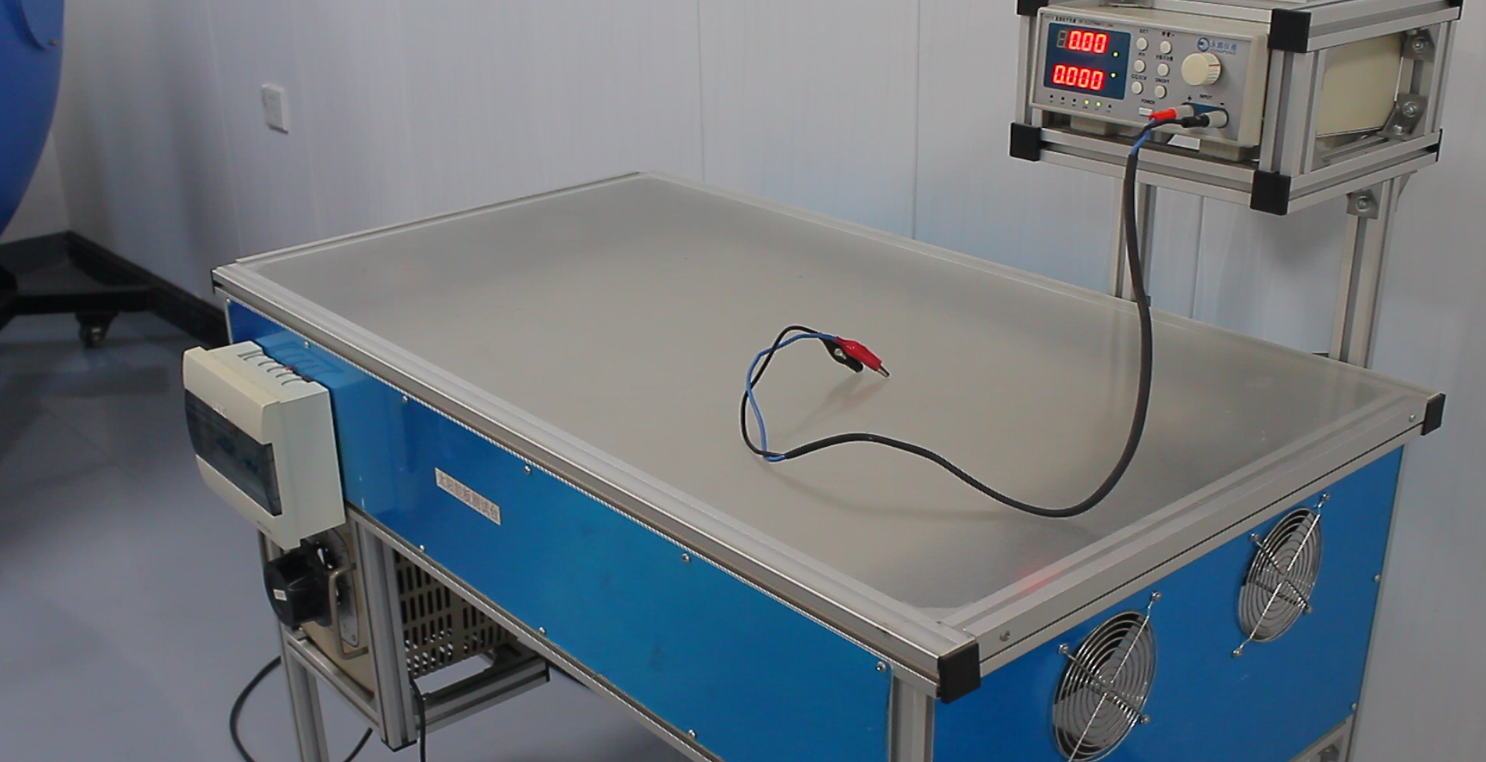

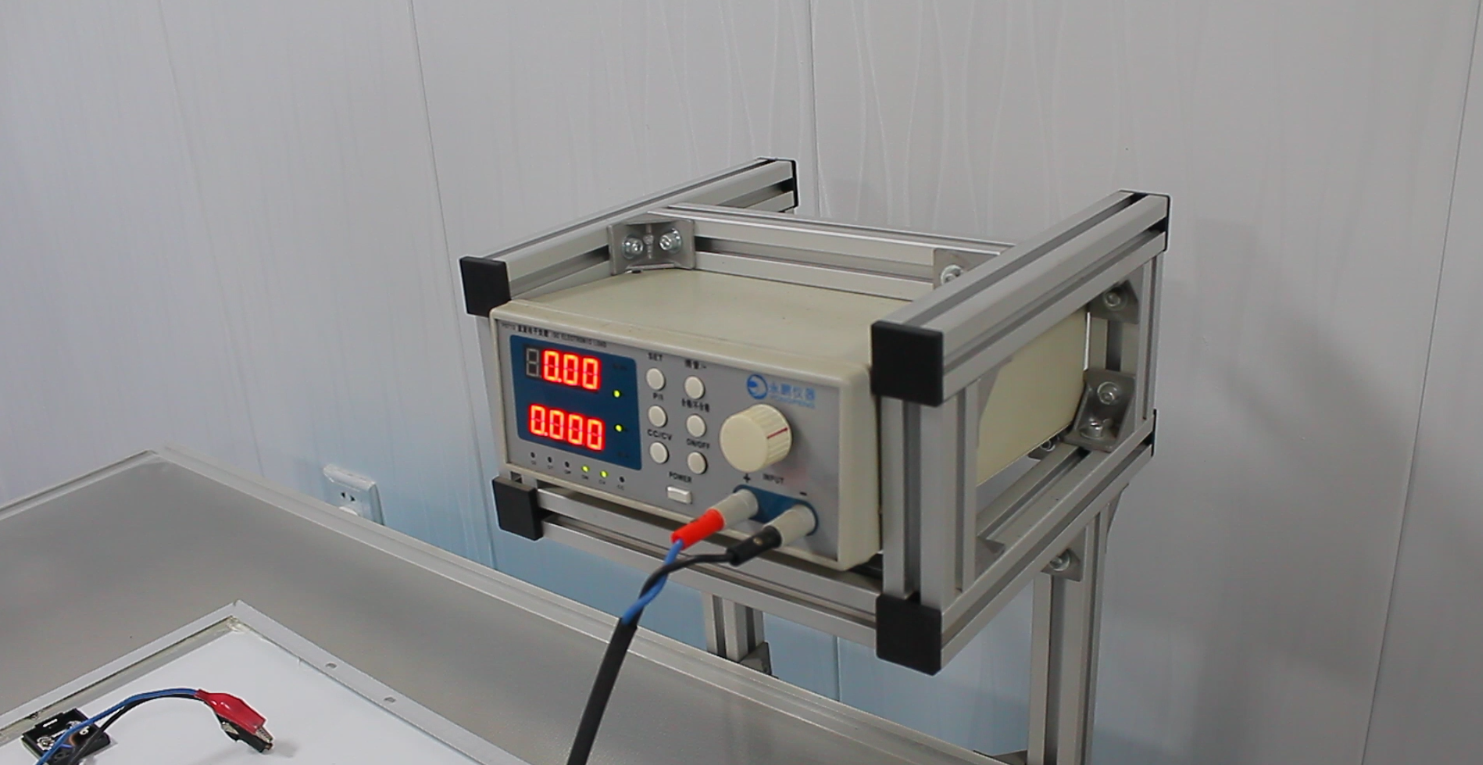

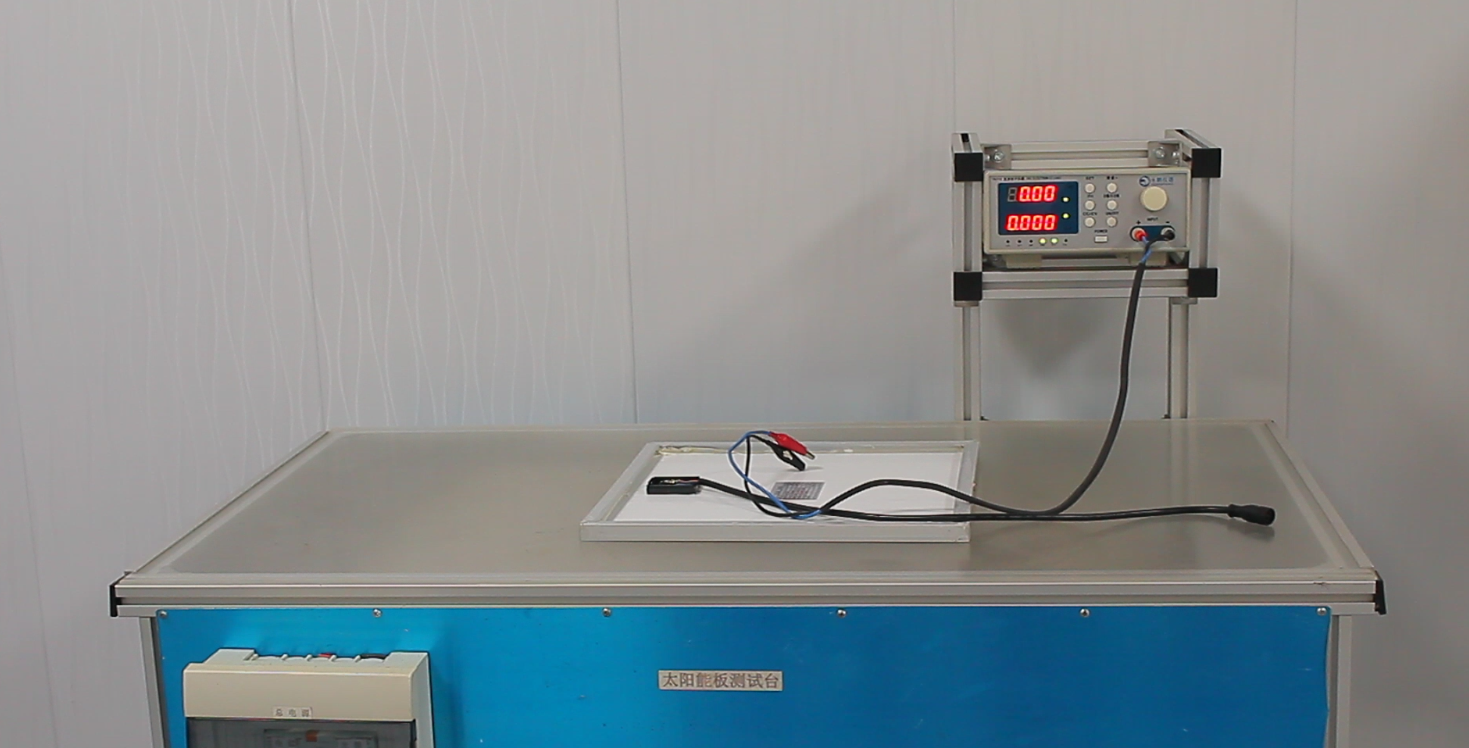

A Solar Panel Test Bench is a specialized setup or system used to test, evaluate, and analyze the performance and quality of solar panels under controlled conditions.

It helps verify whether a solar panel meets:

-

Its rated power output (Wattage)

-

Voltage and current characteristics

-

Conversion efficiency

-

Thermal performance

-

Durability under simulated sunlight, heat, and weathe

How is solar panel testing carried out?

Solar panel testing is carried out to evaluate the performance, safety, durability, and efficiency of solar photovoltaic (PV) modules. It ensures panels meet industry standards (like IEC 61215 and IEC 61730) and are reliable under various environmental conditions.

Here’s a breakdown of how solar panel testing is carried out:

1. Visual Inspection

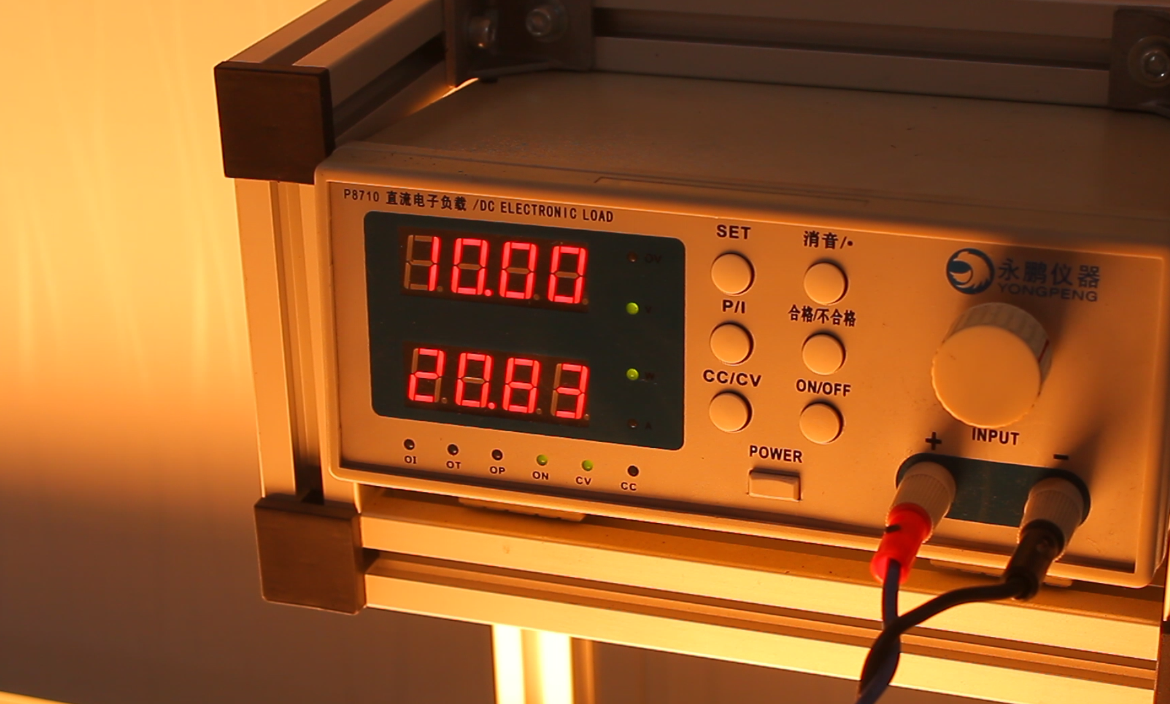

2. Electrical Performance Testing (I-V Curve)

3. Thermal Cycling Test

4. Damp Heat Test

5. Mechanical Load Test

6. UV Exposure Test

7. Insulation & Wet Leakage Test

8. Bypass Diode Function Test

9. Degradation and PID Testing (Potential Induced Degradation)

10. Real-World Performance Testing (Optional)

Why Testing Matters

-

Ensures product warranty reliability

-

Prevents costly field failures

-

Helps qualify for certifications (TÜV, IEC, UL)

-

Verifies batch consistency in manufacturing

Gebosun Lighting Laboratory

Lamp bead aging detection

EMC testing system

Lamp bead aging detection

integrating sphere

Lamp bead aging detection